Dispenser Maintenance 101

The dispenser is the only retail device that allows a customer direct access to your UST system. As such, it needs to be properly maintained for the safety of your guests and your investment. Owners and operators should pay close attention to the integrity of their dispensers. We’ve put together a short list of common issues dispensing units may exhibit. The photos here are all examples of dispensing equipment that has degraded or isn’t being used properly.

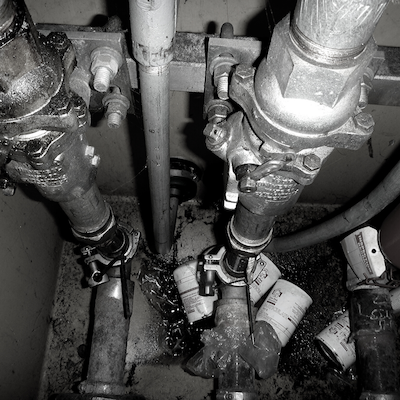

Liquid & Debris

Under dispenser containment, just like any other containment equipment, should be kept free and clear of all liquid and debris. Containment equipment isn’t meant to store liquid for an extended period. In the event of a release, these containments need to be able to hold as much product as possible. If they’re full of mud, water, and leaves, they can’t operate at maximum efficiency.

Filters

For most facilities, it’s recommended that filters be changed at least once a year. However, facilities with a higher throughput may need to be changed more frequently. The life of a filter will depend on fuel output, fuel quality, and correct installation. When a filter has been replaced, be sure to dispose of the old filter properly. Leaving the old filter under the dispenser to “dry out,” especially under a dispenser with no containment, is not acceptable.

Hoses

Overtime, dispenser hoses will deteriorate and require replacement. If you start to notice cracks or splits, it’s past time to replace the hose. If no visible deterioration is present, take a clean towel and wipe the length of the hose. If any petroleum residue is present, replace the hose. Breakaways, whip hoses, and hose retrieval devices should also be monitored for signs of deterioration and dysfunction.

Liquid Sensors

Liquid sensors must be properly placed in order to get accurate reads and function as designed. Sensors should be located at the lowest point in the sump or within the bottom two inches. In addition, the sensor should also be anchored securely and placed in the area closest to the piping or wherever product is most likely to collect within the sump. In this photo, you can see that the sensor has been moved to rest above the piping equipment.

Nozzles

Operators should pay close attention to the “Remove-by Date” on the hanging hardware attached to the dispenser, including nozzles, swivels, and breakaways. Manufacturers recommend these components be replaced at least every 5 years, based on testing conducted by the manufacturer.

Card Skimmers

Skimming equipment can be placed on the exterior or interior of a dispensing unit. Over the years, skimming devices have become smaller and harder to detect. Train your employees on warning signs that a dispenser has been tampered with, such as pry marks, scratches, and discolored card readers or keypads.